About this item

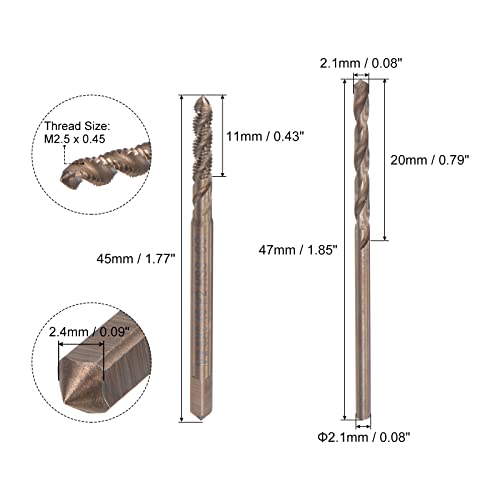

- Tap and Drill Bit: Tap thread size: M2.5 x 0.45, drill bit diameter: 2.1mm / 0.08". Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance.

- Spiral Flute Tap: Spiral flute design, upward chip removal, right hand thread cutting, fast tapping with accuracy. Suitable for processing blind holes and sticky materials, and tapping aluminum, die steel, stainless steel, bronze, hard plastics, etc.

- Twist Drill Bit: Spiral chip space design for fast and clean chip removal. Sharp cutting edge provides smooth cutting and no glitches. Chips are not easy to stick to the tool.

- Usage of Tap: Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Machine taps are suggested to be used with tap collets with overload protection.

- Tips of Drill Bit: Suitable lubricant is conducive to cutting or cooling, making cutting easier, improving smoothness and dimensional accuracy. Select an appropriate feed rate and cutting speed to improve the tool life.

Product Description Information Taps has straight flute thread taps, spiral flute thread taps, spiral point thread taps and thread forming taps. They are also classified into hand taps and machine taps according to the usage. Hand taps are operated by tap wrenches. Machine taps are suggested to be used with the tap collet with overload protection, and hand use or electric drills use is easy to cause breakage to the tap. Taps are prone to chipping or breaking due to speed overload or non-vertical tapping. Use the correct tapping tools, such as tapping wrench, tapping machine. Spiral Flute Tap Thread Tap Spiral flute design, upward chip removal, right hand thread cutting, fast tapping with accuracy. It has high wear resistance, high cutting speed, high strength and hardness. Cobalt High Speed Steel Tool Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance. Specially designed for drilling stainless steel. Easy to Use Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Wide Applications Suitable for processing blind holes, deep holes, and sticky materials, and tapping stainless steel, aluminum, die steel, bronze, hard plastics, etc.. Recommended feed rate: General steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min. Tips: The torque caused by too fast feed speed is too large, which can easily cause the tap to break. Micro taps (such as M1-M3.5) are mainly used in clocks and watches, as well as for making holes in wood and soft metals with lower hardness. Twist Drill Bit Spiral Flute Bit Spiral chip space design for fast and clean chip removal. Sharp cutting edge provides smooth cutting and no glitches. Cobalt High Speed Steel Tool Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance. Specially designed for drilling stainless steel. Wide Applications For drilling stainless steel, aluminum, bronze, hard plastics, etc. Suitable lubricant is conducive to cutting or cooling, making cutting easier, improving smoothness and dimensional accuracy. Combined with the material to be processed, select an appropriate feed rate and cutting speed to improve the tool life and obtain better processing accuracy and performance.

About this item Tap and Drill Bit: Tap thread size: M2.5 x 0.45, drill bit diameter: 2.1mm / 0.08". Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance. Spiral Flute Tap: Spiral flute design, upward chip removal, right hand thread cutting, fast tapping with accuracy. Suitable for processing blind holes and sticky materials, and tapping aluminum, die steel, stainless steel, bronze, hard plastics, etc. Twist Drill Bit: Spiral chip space design for fast and clean chip removal. Sharp cutting edge provides smooth cutting and no glitches. Chips are not easy to stick to the tool. Usage of Tap: Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Machine taps are suggested to be used with tap collets with overload protection. Tips of Drill Bit: Suitable lubricant is conducive to cutting or cooling, making cutting easier, improving smoothness and dimensional accuracy. Select an appropriate feed rate and cutting speed to improve the tool life. Product Description Information Taps has straight flute thread taps, spiral flute thread taps, spiral point thread taps and thread forming taps. They are also classified into hand taps and machine taps according to the usage. Hand taps are operated by tap wrenches. Machine taps are suggested to be used with the tap collet with overload protection, and hand use or electric drills use is easy to cause breakage to the tap. Taps are prone to chipping or breaking due to speed overload or non-vertical tapping. Use the correct tapping tools, such as tapping wrench, tapping machine. Spiral Flute Tap Thread Tap Spiral flute design, upward chip removal, right hand thread cutting, fast tapping with accuracy. It has high wear resistance, high cutting speed, high strength and hardness. Cobalt High Speed Steel Tool Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance. Specially designed for drilling stainless steel. Easy to Use Used on drilling machines, tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Wide Applications Suitable for processing blind holes, deep holes, and sticky materials, and tapping stainless steel, aluminum, die steel, bronze, hard plastics, etc.. Recommended feed rate: General steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min. Tips: The torque caused by too fast feed speed is too large, which can easily cause the tap to break. Micro taps (such as M1-M3.5) are mainly used in clocks and watches, as well as for making holes in wood and soft metals with lower hardness. Twist Drill Bit Spiral Flute Bit Spiral chip space design for fast and clean chip removal. Sharp cutting edge provides smooth cutting and no glitches. Cobalt High Speed Steel Tool Cobalt high speed steel tool features high hardness (HRC65-66) and high red hardness, high wear resistance. Specially designed for drilling stainless steel. Wide Applications For drilling stainless steel, aluminum, bronze, hard plastics, etc. Suitable lubricant is conducive to cutting or cooling, making cutting easier, improving smoothness and dimensional accuracy. Combined with the material to be processed, select an appropriate feed rate and cutting speed to improve the tool life and obtain better processing accuracy and performance.

Reviews

There are no reviews yet.