About this item

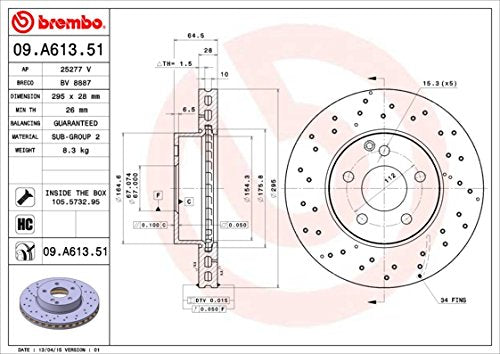

- Outside Diameter (mm) 295; Nominal TH (mm) 28; Min TH (mm) 26

- Environmentally friendly, solvent free UV coating offers superior protection of the disc, including braking plate surfaces. Includes new intelligent marking location for immediate control of the minimum thickness.

- High Carbon cast iron minimizes noise and vibration and provides maximum performance and enhanced driving comfort.

- Drilled Brake Discs

- Includes a fixing screw kit with all the necessary hardware for simple, more efficient and safer installation.

From the manufacturer Brake discs with UV coating Your allies against corrosion. Standard painting UV Coating Resistance to corrosion Medium High Medium It can contain up to 15% of volatile organic compounds VOCs Total abatement of volatile organic compounds VOCs Health It can contain toxins, such as methanol No health threatening components High resistance Limited chemical resistance, for instance against wheel cleaners High resistance to chemical agents Energy consumption 4.67 kWh/disc 0.08 kWh/disc UV Coating Benefits: Resistance to corrosion, humidity and temperatures UV discs assure greater resistance to corrosion, as confirmed by both Spray Chamber test and Resistance tests to humidity and high temperatures. UV coating is applied on the outer edges of the disc, on the hub and on the braking surface: assures the product's integral resistance to corrosion. Intelligent marking The presence of the marking on the disc hub allows the installer to verify, without needing to remove the disc, the minimum thickness to replace the disc. The paint used is water-based and does not require solvents. The ultraviolet ray paint process is also extremely efficient in terms of energy Ready for use! The protective paint coating, also on the braking surface, assures complete protection of the product until assembly and streamlines the mechanic's daily work, preventing the removal of the oil from the disc. ARE YOU USING THE RIGHT BRAKES? How Do You Recognise Whether A Product Is A Brembo Original Check The Box Besides the characteristics Brembo red, the boxes depict the faces of employees; If the box is different, you are most certainly looking at a counterfeit product! Lastly, check to make sure that there are no signs of tampering on it. Check The Hologram And Scan The Qr Code Ensure that the counterfeit-proof Brembo hologram is present on the product label and, for further confirmation that it is original, scan the unique QR Code on the product's sealed box. Verify The Marking On The Product All the brake discs are marked with the Brembo part number and logo and with the ECE R 90 approval (available for part numbers manufactured from November 2016). There is also an indication of the minimum thickness (Min.Th.) for replacement of the disc itself.

About this item Outside Diameter (mm) 295; Nominal TH (mm) 28; Min TH (mm) 26 Environmentally friendly, solvent free UV coating offers superior protection of the disc, including braking plate surfaces. Includes new intelligent marking location for immediate control of the minimum thickness. High Carbon cast iron minimizes noise and vibration and provides maximum performance and enhanced driving comfort. Drilled Brake Discs Includes a fixing screw kit with all the necessary hardware for simple, more efficient and safer installation. From the manufacturer Brake discs with UV coating Your allies against corrosion. Standard painting UV Coating Resistance to corrosion Medium High Medium It can contain up to 15% of volatile organic compounds VOCs Total abatement of volatile organic compounds VOCs Health It can contain toxins, such as methanol No health threatening components High resistance Limited chemical resistance, for instance against wheel cleaners High resistance to chemical agents Energy consumption 4.67 kWh/disc 0.08 kWh/disc UV Coating Benefits: Resistance to corrosion, humidity and temperatures UV discs assure greater resistance to corrosion, as confirmed by both Spray Chamber test and Resistance tests to humidity and high temperatures. UV coating is applied on the outer edges of the disc, on the hub and on the braking surface: assures the product's integral resistance to corrosion. Intelligent marking The presence of the marking on the disc hub allows the installer to verify, without needing to remove the disc, the minimum thickness to replace the disc. The paint used is water-based and does not require solvents. The ultraviolet ray paint process is also extremely efficient in terms of energy Ready for use! The protective paint coating, also on the braking surface, assures complete protection of the product until assembly and streamlines the mechanic's daily work, preventing the removal of the oil from the disc. ARE YOU USING THE RIGHT BRAKES? How Do You Recognise Whether A Product Is A Brembo Original Check The Box Besides the characteristics Brembo red, the boxes depict the faces of employees; If the box is different, you are most certainly looking at a counterfeit product! Lastly, check to make sure that there are no signs of tampering on it. Check The Hologram And Scan The Qr Code Ensure that the counterfeit-proof Brembo hologram is present on the product label and, for further confirmation that it is original, scan the unique QR Code on the product's sealed box. Verify The Marking On The Product All the brake discs are marked with the Brembo part number and logo and with the ECE R 90 approval (available for part numbers manufactured from November 2016). There is also an indication of the minimum thickness (Min.Th.) for replacement of the disc itself.

Reviews

There are no reviews yet.